One Stop Solution Provider For Wiring Harness Assembly 0086-15986797622 vivi

@leadtech-in.com

Views: 0 Author: Site Editor Publish Time: 2023-07-31 Origin: Site

F-shape crimping

In F-shape crimping, after the cold press connection, the terminal insulation crimping area in the terminal is not allowed to puncture the wire core, single-wire F-shape crimping as shown in Figure 9a, double-wire F-shape crimping as shown in Figure 9b. Eat crimp type of application more, a large part of the domestic car wiring harness used in the sheath within the terminal are used in this crimp type, such as Guangzhou Toyota, FAW and other production of the car wiring harness are used.

After the terminal cold press connection, does not allow the terminal stab wire insulation, crimping insulation crimping area in the two outer sides must be in a pair of parallel planes, single wire WRAP-shaped crimp as shown in Figure 10a, double wire WRAP-shaped crimp as shown in Figure 10b. This crimp type is used in the instrument panel wiring harness of the China Junjie with the instrument display and the combination switch docking sheath terminals, the Great Wall Genie, Haval M1, Hurray and BYD F3, F3DM hybrid engine wiring harness and ECU docking sheaths within the small terminals are also used in this crimp type.

After the cold press connection, the terminal insulation crimp area in the terminal is not allowed to puncture the wire insulation, crimping after the insulation crimp area of the terminal closure mouth to the positive contact or separate, single wire O-shaped crimping as shown in Figure 11a, double wire O-shaped crimping as shown in Figure 11b. This crimp type is used in the terminal block of the China Junjie instrument panel wiring harness that interfaces with the ECM.

L-shaped crimp

Overlapping crimp

Non-standard special tail crimp

Usually with a secondary tail self-locking sheath, equipped with terminals in the application of the terminal tail must do special crimping, commonly used high tail, wide tail crimping, that is, insulation crimping area crimping height or width needs to be within a numerical value in order to meet the requirements of the self-locking, or else the tail of the second self-locking may fail, resulting in lower quality and more hidden dangers. The shape of the terminal tail crimp is determined by the sheath itself, in general, non-standard special tail crimp has the following 3 crimp types.

6.1. European and American type high tail crimp

This crimp type must be used when the terminal and the sheath are correctly assembled and the direction of the crimp closure at the terminal core and insulation is on the same side of the sheath as shown in Figure 14, otherwise the self-locking characteristics cannot be satisfied. The advantages of this type of crimping is that the terminal in the sheath of good stability, there will be no phenomena such as retreat and rotation, the disadvantage of the insulation crimp area in the terminal and wire contact surface is small, the insulation crimp area in the wire fixed performance is not good. This crimp type is applied to the terminals in the docking sheath of the instrument harness and engine compartment harness of Zhonghua Junjie, as well as the terminals in the docking sheath of the immobilizer, the electric mirror switch, the seatbelt switch, the license plate light, and the rear combination light.

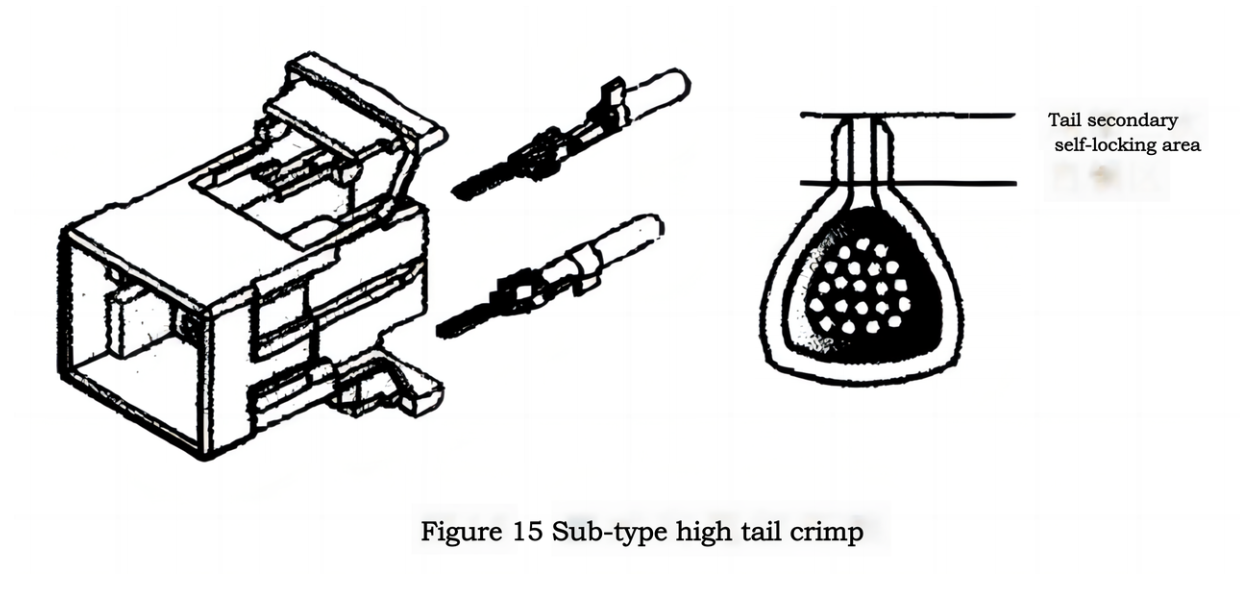

When the terminal and the sheath are properly assembled, the direction of the crimp closure at the terminal core and insulation is on both sides of the sheath, this crimp type is preferred, as shown in Figure 15, because this crimp type better ensures the maximum contact area between the terminal and the wire. The disadvantage is that, when the terminal and the sheath fit precision is not high, the terminal and the sheath are assembled with a certain range of rotation of the terminal, affecting the terminal and the docking terminal can be assembled. This crimp type is used for the terminals in the sheaths that interface with the wiper, washer, and horn switches in the instrument harness of the Zhonghua Junjie; the terminals in the sheaths that interface with the glass lifter switch on the left front door harness of the Great Wall Hyunli, and the terminals in the sheaths that interface with the cabin harness and the instrument panel harness and with the floor harness of the Great Wall Elf also use this crimp type.

This type of crimp is suitable for terminals of size 6.3 and above and is less commonly used, but can sometimes be used inside the sheath of some power supply inserts, as shown in Figure 16. This crimp type is used in the Great Wall Elf for the terminals inside the power outlet sheath that mates the cabin wiring harness to the center power distribution box, and for the relay terminals in power distribution box #2 in the cabin wiring harness.

In this paper, through the elaboration of each functional part of the terminal, each functional area, and some important parameters of the terminal cold stamping connection (crimp height and width, crimp head length, material tape cutting length, before and after the protection port requirements, buffer transition zone in the core and insulation layer position, terminal deformation), as well as a detailed analysis of the six types of crimp type, for the reference of peers, and look forward to the correction of peers.

Lead Tech is a professional company who has been dealing with automotive connectors supplying for over 10 years,

who happens to be a specialist mainly help you solve your supplying urgencies.

If you are interested in more articles, feel free to click likes and reach us @www.leadtech-in.com